Sep 1, 2012 | News & Events

We are proud to be supporting Gas Safety Week taking place 10th -16th September 2012

Gas Safety Week is co-ordinated by Gas Safe Register, the official list of gas engineers who are legally allowed to work on your gas boiler, gas cooker and gas fire. Gas Safety Week aims to raise awareness of gas safety and the importance of taking care of your gas appliances. It is a national campaign with events, advertising and PR taking place across the country to help keep the nation Gas Safe.

Badly fitted and poorly serviced gas appliances can cause gas leaks, fires, explosions and carbon monoxide poisoning. Every year thousands of people across the UK are diagnosed with carbon monoxide poisoning. It is a highly poisonous gas. You can’t see it, taste it or smell it, but it can kill quickly with no warning.

By taking care of your gas appliances properly you are taking care of your home and your loved ones. Follow these top tips to help keep you and your family gas safe:

- Make sure only a Gas Safe registered engineer works on your gas appliances. Illegal gas fitters can put your life at risk

- Always check the engineer’s Gas Safe Register ID card

- Make sure gas appliances have a regular service and a gas safety check every 12 months

- Look out for warning signs that your gas appliances aren’t working correctly e.g. lazy yellow or orange flames instead of crisp blue ones, black marks on or around the appliance and too much condensation in the room

- Know the signs and symptoms of carbon monoxide poisoning – headaches, dizziness, breathlessness, nausea, collapse and loss of consciousness

- Install an audible carbon monoxide alarm

- If you smell gas call the gas emergency number on 0800 111 999

For gas safety advice or to find and check an engineer visit the Gas Safe Register website at www.GasSafeRegister.co.uk. Alternatively call the free helpline on 0800 408 5500.

Feb 17, 2012 | News & Events

Boilers with wide modulation ratios can improve efficiencies and comfort while reducing wear and tear on components – but what does the term mean, and how can installers explain it, and its benefits, to end users? Here Alister Maclachlan, product director at Vokèra, provides some advice following the launch of Vokèra’s Linea One boiler that boasts a modulation ratio of 10 : 1.

In recent years some boiler manufactures have started to talk about modulation ratios – but what does the term mean and, more importantly, how does the end user benefit?

In simple terms, the modulation ratio is a boiler’s ability to reduce its maximum output to its minimum output. A narrow modulation range gives a poor ratio whereas a wide range provides a good ratio. For example, if a boiler has a maximum output of 30kW and a minimum output of 7.7kW its modulation ratio is less than 4:1. Meanwhile, a boiler with a maximum output of 30kW and a minimum output of 3kW has a wider (hence better) modulation ratio of 10:1. As a general rule, for a boiler to be classed as having a ‘good’ modulation ratio its minimum output should be one fifth or one sixth of its maximum output.

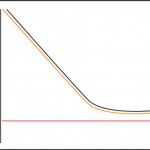

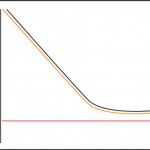

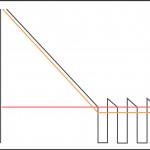

High Modulation Ratio Ignition Sequence

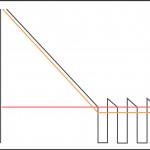

Low Modulation Ratio Ignition Sequence

There are two important reasons why a good boiler modulation ratio is preferable – and understanding these reasons can help installers explain the benefits to end users.

Firstly, a good boiler modulation ratio reduces constant on/off cycling, improving efficiency and boiler longevity. For example, if a boiler has a high maximum output – let’s say 40kW – yet only has a modulation ratio of 4:1 it will only be able to modulate down to 10kW. However, when most rooms have reached the required temperature and radiator TRVs have closed, the demand on the boiler will be considerably less than 10kW. This means that the minimum output of the boiler will be higher than it needs to be, so the boiler will constantly switch on and off – leading to fuel inefficiency and unnecessary wear and tear on its components and parts.

A boiler with a high maximum output and a good modulation ratio, however, will be able to modulate down to an extremely low output, reducing wear and tear on primary components (fewer on/off cycles increase component longevity) and optimising fuel efficiency.

The second reason is uniquely associated with combi boilers, as it concerns the stability of domestic hot water (DHW). A boiler with a poor modulation ratio won’t be able to maintain a stable DHW flow temperature at a low flow rate, and might even cause the burner to switch off during operation. This can be a significant issue for end users who prefer showers over baths or for those who require a constant DHW outlet temperature – for example where there are young children or elderly people in a household, who are at a higher risk of scalding.

So when selecting a combi boiler it’s crucial to consider modulation ratios – and to remember that performance isn’t just about kW output. Nowadays 40kW combis are commonplace, having been introduced to improve hot water flow rates; in the 1980s a typical combi boiler had an output of 24kW (80,000BTUs) and a DHW flow rate of around 9.5l/pm at a 35oC differential, leading to end user gripes about hot water performance. However, installing a combi boiler with a high maximum output and a poor modulation ratio in a typical UK property is unlikely to deliver optimal efficiency, or comfort.

Let’s take a three-bedroom semi-detached house, built in the 1960s, as an example. This type of dwelling will probably only need a maximum of 15kW for space heating, and significantly less when it has reached temperature, especially if the property is insulated and has heating controls fitted. Hence a 40kW combi boiler that can only modulate down to 10kW isn’t good news for the customer either in the short or long term; as well as resulting in DHW instability and temperature fluctuations it will be unable to deliver fuel economy (the end user will of course be expecting their new boiler to deliver savings), and will probably suffer from early component failure.

Installers have a key role to play in ensuring that UK heating systems become more efficient, and end users will very often turn to them for advice. We believe that an increasing number of astute installers are beginning to recognise that if a boiler can boast a wide modulation ratio it will deliver significant benefits. It is however important to demonstrate this to customers, as it could help them in their decision making process. Manufacturers should be able to assist by providing diagrams and literature, which can help to explain the concept – and benefits – in a simple, easy-to-understand way.

Vokèra has made a significant investment in the development of boilers with excellent modulation ratios. Our Linea One 38kW combi boiler boasts a class-leading 10:1 modulation ratio, enabling it to modulate its output to 10 per cent of its maximum – 38kW down to 3.8kW.

Good modulation ratios offer a range of benefits – including increased fuel efficiency, end user comfort and boiler longevity.

For more information about the Vokèra Linea One boiler, click here

Nov 22, 2011 | News & Events

Vokera Verve

Vokera launches high power system boiler

Vokèra is pleased to announce its latest product launch, a new large domestic and light commercial system boiler Verve. The 47kW high-power boiler is designed to offer installers a solution for both large domestic and light commercial boiler applications.

Adding to Vokèra’s comprehensive range of boilers, the Verve offers a 90 per cent efficiency rating and can lead to reduced running costs of up to 35 per cent – making it one of the greenest high-power domestic boilers on the market.

Installers will find both the electronic regulation functions and heat engine design very familiar, being similar to those used on standard domestic boilers. The unit itself is also relatively lightweight weighing in at just 39 kilograms, meaning the Verve is easy to handle and easier to fit.

Alister Maclachlan, product director at Vokèra, comments: “We chose to launch the Verve as it offers installers the option to install a high power system boiler that is familiar in design to that of our domestic range, enabling them to expand their scope of work into larger domestic properties or small commercial premises.

The Verve boiler is supplied with an 80+80mm flue configuration enabling the flue to run up to 20m, or the flue can be re-configured with an optional flue adaptor to a 60/100mm or 80/125mm flue configuration. The Verve is supplied with isolating valves, enabling the boiler to be isolated from the system, which is extremely useful on larger systems, where to drain and refill the system could take several hours.

Vokèra also offer a range of options to accompany the Verve, including the highly recommended hydraulic separator, which ensures the appliance is isolated from any changes in the hydraulic flow rate. Also available is the three port valve which helps to speed up installation.

For more information on the Verve boiler click here

Sep 2, 2011 | News & Events

Increases in domestic gas prices mean we will all be feeling the pinch on household budgets more than ever this winter. Alister Maclachlan, product director at Vokèra, looks at how the latest advanced controls can significantly improve the efficiency of a heating system and reduce utility bills – without requiring too much of a financial outlay.

Increases in domestic gas prices mean we will all be feeling the pinch on household budgets more than ever this winter. Alister Maclachlan, product director at Vokèra, looks at how the latest advanced controls can significantly improve the efficiency of a heating system and reduce utility bills – without requiring too much of a financial outlay.

Following the announcement that energy prices are set to rise even further, many homeowners will be looking to reduce their energy usage to combat the price hikes. The Government’s RHI (Renewable Heat Incentive) and Green Deal schemes are designed to help homeowners afford energy saving measures – but aren’t going to provide immediate assistance.

Though the RHI Renewable Heat Premium Payments are now available, providing a one-off payment if a homeowner has a renewable technology installed (depending on the technology and if certain criteria is met), the ongoing tariffs will not be available until late 2012.

Similarly, the Green Deal will not be up and running until the end of 2012 at the earliest. This new scheme will see major energy suppliers offering loans to homeowners who want to install energy efficient measures and technologies.

So, with help from the RHI and Green Deal being some way off, how can installers help homeowners to find a cost-effective way to be more efficient? There is clearly a need for an immediate, affordable solution – and this is where the latest intelligent heating and hot water controls really come into their own.

Thermostats and controls have been on the market for many years and are an essential part of a modern central heating system; however, more recently manufacturers have invested heavily in further advancing boiler control technology to improve the efficiency of the boiler. In fact, the latest generation of controls offer homeowners even greater command over their heating and fuel usage, and when teamed with a high efficiency boiler, can dramatically reduce fuel bills for the end user.

The very latest innovation to hit the market is built-in OpenTherm technology. It’s estimated that up to 10 per cent of the energy consumed for space heating can be saved by using this type of control with an appropriate HE boiler. Fuel efficiency can be maximised by specifying these controls alongside boilers with higher modulation ratios, for example ratios of 5:1 and higher. For customers looking to reduce their fuel consumption immediately, OpenTherm could be an ideal solution, and is suitable for retrofit as well as new installations (depending on the boilers compatibility with OpenTherm protocol).

The benefit of OpenTherm technology lies in its ability to regulate the temperature of the room more effectively than a standard room thermostat. When a standard ON/OFF room temperature/programmable room thermostat is used, the boiler will usually provide a flow temperature that’s much higher than required for the room to reach the temperature set by the thermostat. This causes the boiler to ‘overshoot’, and as a result the home will actually become too hot. To compensate, the boiler switches off, and the temperature drops again. When the temperature goes below the set-point (the nature of traditional thermostatic controls means a boiler will ‘undershoot’), the boiler turns back on – and so this pattern continues. This frequent ON/OFF cycling results in an inefficient use of fuel and unnecessary wear and tear on boiler parts.

OpenTherm protocol controls are also available as wireless (RF) units, making them particularly suitable for retrofit applications. Vokèra is one of the few manufacturers to offer this type of control in a wireless format. Wireless OpenTherm controls provide a neat installation, something that is particularly ideal for house-proud customers who are concerned about the aesthetics of their home, and are easy to fit. With a 30 metre wireless transmitter, both new and retrofit installations are quick, simple and tidy.

Another recent development in controls has been weather compensation technology, which regulates the output of the boiler in line with the outside temperature, and is particularly effective when unseasonal weather occurs. Using weather compensation will almost always ensure that the boiler is fully condensing and this maximises fuel efficiency. In fact, under the proposed SAP 2009, the installation of a weather compensation control can increase the efficiency of a condensing boiler by up to 3%, enabling efficiencies in excess of 93 per cent. A weather compensation control not only saves energy, it can also ensure a more comfortable environment inside the home too.

While a selection of boilers are being supplied with weather compensation controls included, a key benefit is that existing boilers can be upgraded to include this technology. If fitting an external weather sensor, it is advisable to fit the controls to a north or north-west facing wall to achieve optimum results.

Both OpenTherm and weather compensation controls offer an affordable, cost-effective way to improve energy efficiency – and could provide a useful stop-gap until other measures, such as a more efficient boiler or a renewable technology, can be fitted.

When specifying controls it’s worthwhile looking for any additional features that will add to the usability of the control, ensuring the homeowner can make the most of their heating system, manage their energy efficiently and maximise comfort. For example, the OpenTherm protocol RF control from Vokèra includes a handy holiday function. This allows the end-user to set the control for the duration of the holiday, and the temperature at which the boiler should operate at during this period and for when they return.

If a control boasts an optimisation function, this means it will start the boiler working before the programmed ‘ON’ time, so the desired temperature is reached for when the homeowner wants it. Some controls also give homeowners access to useful information too, such as the current and target room temperatures.

When specifying controls with advanced user functions, it is important to ensure the homeowner is properly briefed when the unit is installed. This will ensure the customer knows how to operate the controls and that the maximum energy savings can be achieved.

With fuel prices rising dramatically and the effects of the economic downturn still being felt, there has never been a more important time to ensure a home’s central heating system runs as effectively and efficiently as possible. Installers can provide valuable information to homeowners about the advantages of intelligent controls to help them reduce their energy usage now, so they are better prepared to manage the cost of their utility bills in the future.

Our website has a wealth of information on boilers, controls and renewables, to help you save on your fuel bills

Jul 21, 2011 | News & Events

Renewable Heat Premium Payment Grant finally announced

If you are installing renewables, then you need to read on, the Government Renewable Heat Premium Payments (RHPP) have finally been announced and will be availale from 1st August 2011.

What is great about the RHPP is that so far the scheme seems to be very simple. This will help its success – something we saw with the boiler scrappage scheme, which was kept very clear and subsequently worked very well.

The premium payments demonstrate that the Government is backing renewable technologies and recognising their importance in meeting our carbon reduction commitments

The announcement from the DECC on 21st July 2011 has confirmed the scheme will start on 1 August. Installers who have not started need to get prepared. Vokèra’s advice to installers is to get MCS accredited, finish off any necessary training so they can offer these additional services to their customers alongside their core business.

The RHI (Renewable Heat Incentive) tariffs which are expected to launch in October 2012, will further encourage their uptake. We are expecting announcements regarding the criteria and amount of ongoing tariffs for households who invest in the eligible renewable heating technologies later this year.

Vokèra is urging the Government to announce the RHI tariff criteria as soon as possible. The ideal situation would be that the criteria is the same for the tariff as it is for the RHI Premium Payment, so people are assured of this continued support. Alternatively, the Government should allow homeowners who do not meet the criteria a chance to implement any necessary changes and reapply.

RHPP Factfile

What is the RHPP?

The Renewable Heat Premium Payment scheme is a Government scheme that gives householders a one-off payment to help them buy renewable heating technologies – solar thermal panels, heat pumps and biomass boilers. It will run between 1 August 2011 and 31 March 2012. It only runs for eight months – because from October 2012, the Renewable Heat Incentive tariffs will be launched for the domestic sector and the Green Deal will come into force.

What is the criteria?

Where practical, loft insulation to a minimum of 250mm and cavity wall insulation needs to be in place. The products installed and the installer must be MCS (Microgeneration Certification Scheme) approved.

Following installation the homeowner will complete two surveys and could have the opportunity to have a free meter installed to monitor the energy performance.

How much is it worth?

ALL HOUSES

£300 – Solar thermal -voucher valid for 3 months

HOUSES NOT HEATED BY GAS FROM THE GRID

£850 – Air source heat pump – voucher valid for 5 months

£950 – Biomass boiler -voucher valid for 6 months

£1250 – Ground source heat pump -voucher valid for 6 months

How do you apply?

Apply online at the Energy Saving Trust website. If the criteria is met, a voucher will be issued, which must be returned before its expiry date with a copy of the invoice and certificate from the MCS.

The Scheme will end on the 31 March 2012, or when the allocated funding has been issued.

So, how do we access the RHI tariffs?

Installations that have received the RHPP will be eligible for the RHI tariffs, providing you meet the RHI criteria, which has not yet been finalised. Full details of the scheme and eligibility can be found on the EST website: www.est.org.uk

Jan 5, 2011 | News & Events

Vokèra has announced the launch of the new Linea One, a SEDBUK A rated combi boiler, with high output of 38kW and excellent domestic hot water performance of 15.6 litres per minute.

Vokèra has announced the launch of the new Linea One, a SEDBUK A rated combi boiler, with high output of 38kW and excellent domestic hot water performance of 15.6 litres per minute.

Linea One is our flagship combi boiler, boasting an array of exceptional features, benefits and efficiency for maximum end user comfort as well as offering a 5 year parts and labour guarantee as standard for total peace of mind.

The Linea One has one of the lowest NOx emissions in its class, with just 29mg/kWh and has an outside weather sensor included in the box, enabling it to be up to 93% efficient*

Alister Maclachlan, technical director, for Vokèra, said: “We’re really excited about the new Linea One, as we believe it offers customers a high quality, high performance, modern boiler which features some of the latest technology in energy efficiency.”

A snapshot of Linea One’s functions:

Intelligent ‘Pre Heat Memory’ function

The Linea One incorporates an intelligent domestic hot water ‘Pre Heat Memory’ function that, when selected, adapts the appliance pre-heat function to match your typical daily hot water usage pattern. Over a 1-week period, the boiler monitors at what times and how much hot water your household uses, thereafter the pre-heat function of the boiler is automatically adapted to suit your lifestyle, ensuring that there is always an immediate supply of hot water when you need it.

‘Comfort’ function

The ‘Comfort’ function allows you to set a fixed outlet temperature for DHW within the range 35°C to 45°C (factory set at 40°C). By choosing to operate this function you ensure that your DHW is of a comfortable and safe temperature which is especially useful if there are young children or elderly relatives in the home.

To find out more email [email protected]

*Based on SAP 2009

Vokèra has announced the launch of the new Linea One, a SEDBUK A rated combi boiler, with high output of 38kW and excellent domestic hot water performance of 15.6 litres per minute.

Vokèra has announced the launch of the new Linea One, a SEDBUK A rated combi boiler, with high output of 38kW and excellent domestic hot water performance of 15.6 litres per minute.